PROTOLON (FL)-LWL 8.7/15kV Medium Voltage Flat Reeling Cable with Integrated Fibre-Optics – High-Performance Power & Data Transmission Solution

Engineered for Port Shipbuilding and Heavy-Duty Maritime Applications – Flexible, Oil & UV Resistant, Compliant with Global Standards

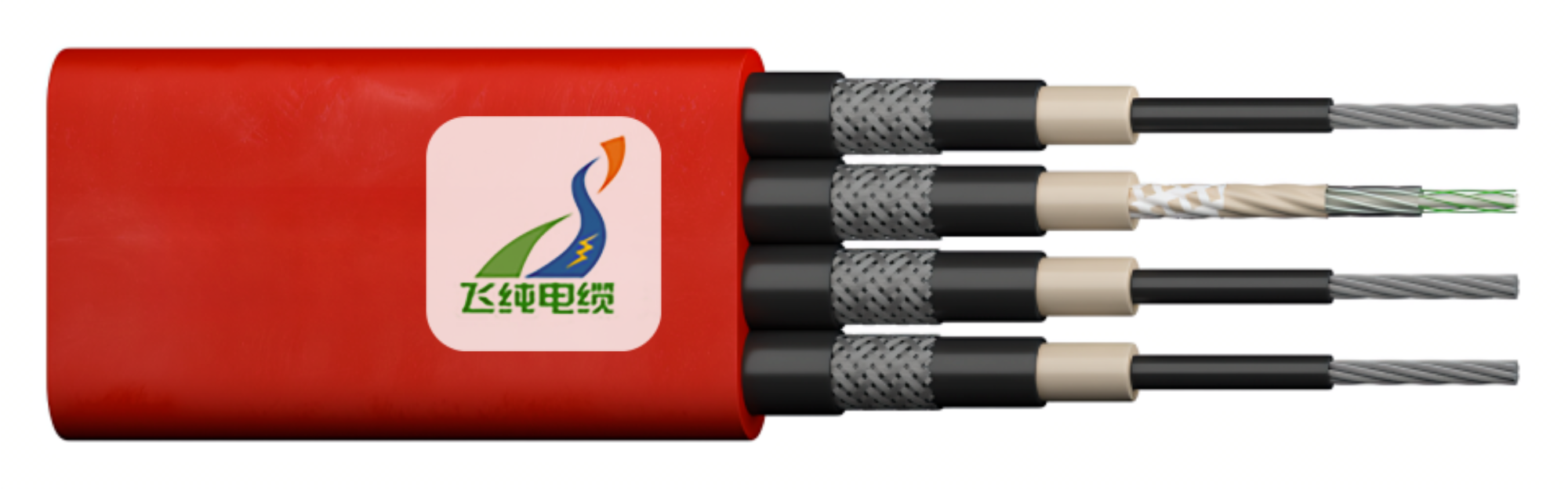

The PROTOLON (FL)-LWL (N)TSFLCGEWOEU 8.7/15kV is a flexible medium voltage flat reeling cable designed for the simultaneous transmission of power and data. It integrates fiber-optic elements, making it ideal for high-demand industrial environments where reliable data communication and power supply are crucial.

This cable is specifically engineered to withstand high mechanical stresses, including dynamic tensile loads, multiple directional changes within one plane, and movement over rollers.

Applications

This high-performance reeling cable is ideal for mobile heavy-duty equipment, such as:

Container cranes with fast-moving operations

Large-scale port and industrial machinery

Mining and construction equipment requiring high flexibility

Reeling drum systems that undergo frequent movement

Key Standards and Compliance

The cable adheres to the following international standards, ensuring reliability and safety:

DIN VDE 0250-813 – Electrical requirements for flexible reeling cables

DIN EN 60228 / IEC 60228 / VDE 0295 – Conductor material and construction

DIN EN 60811-404 / IEC 60811-404 – Resistance to environmental and mechanical stress

HD 2216 – Optical fiber requirements

DIN VDE 0298-4 – Current-carrying capacity and installation guidelines

Construction and Materials

Conductor: Finely stranded, tinned copper (Class 5)

Insulation: High-performance EPR rubber (PROTOLON HS) with a semi-conductive inner layer

Core Arrangement: Parallel core design with a split and concentrically distributed earth conductor

Outer Sheath: Made of polychloroprene (PCP) rubber with a special compound (5GM5), offering superior durability

Integrated Fibre-Optics

This cable features six optical fiber tubes, each containing one, two, or three optical fibers, ensuring high-speed and stable data transmission. Fiber options include:

Multi-mode graded index (G62.5/125 µm, G50/125 µm)

Single-mode graded index (E9/125 µm)

Bandwidth capacity exceeding 400 MHz at 850 nm

Low attenuation rates (< 0.3 dB/km at 1550 nm)

High resistance to chromatic dispersion at 1300 nm and 1550 nm

Technical Performance

Rated Voltage: 8.7/15 kV (Max voltage: 17.5 kV)

Test Voltage: 24 kV

Operating Temperature:

Fixed installation: -50°C to 80°C

Flexible installation: -35°C to 80°C

Max Conductor Temperature: 90°C (continuous use), 250°C (short circuit)

Mechanical Properties:

Permanent tensile strength: 15 N/mm²

Travel speed: Up to 120 m/min (for reeling operations)

Bending radius:

Fixed installation: ≥ 6x cable diameter (D)

Flexible operation: ≥ 10x D

Directional S-type changes: ≥ 20x D

Environmental and Safety Features

Flame-retardant – Compliant with EN/IEC 60332-1-2

Oil-resistant – Suitable for industrial environments with oil exposure

UV and ozone-resistant – Ensures durability in outdoor and extreme conditions

Cable Variants and Electrical Properties

Why Choose PROTOLON (FL)-LWL Reeling Cables?

Designed for High-Stress Applications – Withstands extreme mechanical loads, rapid movement, and frequent bending

Integrated Fibre-Optics – Reliable power and data transmission in a single cable

Superior Material Composition – High-performance EPR insulation and PCP sheath provide durability and flexibility

Compliance with Global Standards – Ensures safety, efficiency, and long service life

Resistant to Harsh Environments – Performs well under oil, ozone, UV exposure, and extreme temperatures

For industries that demand uncompromising performance and durability, the PROTOLON (FL)-LWL (N)TSFLCGEWOEU 8.7/15kV reeling cable is a top-tier solution for mobile equipment and crane applications. Ensure seamless power and data transmission with Feichun Cable’s high-quality reeling solutions!

Cable Variants and Electrical Properties

Product Code | Configuration | Max Tensile Strength (N) | Min Bending Radius (mm) | Conductor Resistance (Ω/km at 20°C) | Current Carrying Capacity (A) |

|---|---|---|---|---|---|

3x35+4x25/4E +1x(12E9LWL) | 1575 | 485 | 0.565 | 138 | |

3x35+4x25/4E +1x(6G62.5LWL) | 1575 | 485 | 0.565 | 138 | |

3x35+4x25/4E +1x(6G62.5LWL) BLACK | 1575 | 485 | 0.565 | 130 | |

3x50+4x25/4E +1x(18G50LWL) | 2250 | 495 | 0.393 | 172 | |

3x50+4x25/4E +1x(6G50LWL) | 2250 | 495 | 0.393 | 172 | |

3x50+4x25/4E +1x(6G62.5LWL) | 2250 | 495 | 0.393 | 172 | |

3x70+4x35/4E +1x(6G62.5) | 3150 | 506 | 0.277 | 212 |

Frequently Asked Questions (FAQ)

Q: What is the PROTOLON (FL)-LWL (N)TSFLCGEWOEU 8.7/15kV cable?

A: It is a flexible, medium voltage flat reeling cable with integrated fibre-optics, engineered for the combined transmission of power and data.Q: What are the primary applications of this cable?

A: It is ideal for heavy-duty mobile equipment in port shipbuilding, container cranes, and other industrial machinery used in harsh maritime environments.Q: What is the rated voltage of the cable?

A: The cable is rated at 8.7/15 kV and is tested up to 24 kV for reliable medium voltage performance.Q: Which international standards does the cable meet?

A: It complies with standards such as DIN VDE 0250-813, DIN EN 60228/IEC 60228, DIN EN 60811-404/IEC 60811-404, HD 2216, and DIN VDE 0298-4.Q: What type of conductor does the cable use?

A: It uses finely stranded, tinned copper conductors (Class 5) that offer excellent electrical conductivity and durability.Q: What insulation material is employed in the cable’s construction?

A: The cable utilizes high-performance EPR rubber (PROTOLON HS) with both inner and outer semi-conductive layers for superior insulation.Q: How does the flat reeling design benefit the cable?

A: Its flat profile minimizes bending stresses, making it ideal for applications with dynamic tensile loads and frequent changes of direction over rollers.Q: What integrated fibre-optic features does the cable offer?

A: It contains six fibre-optic tubes around a central support element, accommodating multi-mode and single-mode fibres for high-speed data transmission.Q: How does the cable support simultaneous power and data transmission?

A: The integrated fibre-optics allow it to deliver both electrical power and data through a single cable system, simplifying installations.Q: What environmental resistances does the cable provide?

A: It is designed to be oil-resistant, UV resistant, ozone resistant, and flame-retardant in accordance with EN/IEC 60332-1-2 standards.Q: What temperature ranges can the cable operate within?

A: For fixed installations, it operates from -50°C to 80°C, and for flexible installations from -35°C to 80°C.Q: What is the maximum continuous operating temperature?

A: The cable can handle continuous operation up to 90°C, with a short-circuit temperature rating of up to 250°C.Q: How does the cable manage mechanical stress?

A: Its design, including a permanent tensile strength of 15 N/mm² and a parallel core arrangement, ensures excellent resistance to mechanical stress.Q: What reeling performance does the cable deliver?

A: It supports high-speed reeling operations with travel speeds up to 120 m/min, ensuring efficient on-site handling.Q: How does the cable’s parallel core arrangement enhance performance?

A: This arrangement ensures even current distribution and improved electrical efficiency, which is critical in demanding applications.Q: How do the integrated fibre-optics improve operational efficiency in port applications?

A: They enable real-time data monitoring and control, essential for automating and optimizing operations in shipyards and ports.Q: What benefits does the outer polychloroprene (PCP) sheath provide?

A: The robust PCP sheath, enhanced with special compounds, offers excellent protection against abrasion, chemicals, and environmental exposure.Q: How is the cable rigorously tested for quality?

A: It undergoes extensive electrical and mechanical testing, including high voltage tests and compliance verification with international standards.Q: In what way does the cable simplify on-site installations?

A: By integrating both power and data transmission into one cable, it reduces wiring complexity and installation time in challenging environments.Q: Why is this cable particularly suited for port shipbuilding and heavy industrial use?

A: Its robust design, integrated fibre-optic capabilities, and adherence to global standards ensure reliable performance under high mechanical and environmental stresses.